The maintenance of a building is not just a conservation activity but a strategic process to ensure safety, efficiency, and sustainability throughout the entire life cycle of the building. Traditionally, corrective maintenance strategies (intervention after failure) or scheduled preventive maintenance (periodic interventions) have been used. However, these approaches have significant limitations: the former exposes to unforeseen risks and costs, while the latter can lead to resource waste and unnecessary interventions.

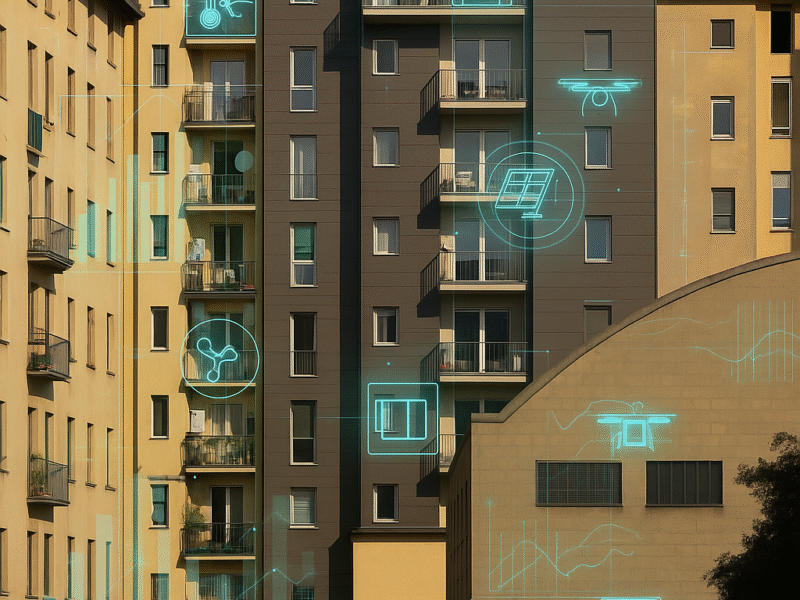

Predictive maintenance, enabled by digital engineering and the integration of emerging technologies such as IoT sensors, artificial intelligence, and digital twins, represents a fundamental evolution today. It allows for the early prediction of failures or degradation, based on continuous analysis of real data, and intervention only when truly necessary. This way, an optimal balance between costs, efficiency, and safety is achieved, while also improving the sustainability of management operations.

Predictive maintenance fits into a broader vision of life cycle management:

Predictive maintenance represents one of the most advanced and strategic applications of digital engineering in construction. Based on a data-driven and proactive approach, it allows for a radical transformation of work management, ensuring greater safety, efficiency, and sustainability.

Thanks to the integration of IoT sensors, artificial intelligence algorithms, and digital twins, buildings become intelligent organisms capable of self-diagnosing and communicating their maintenance needs.

Ultimately, adopting predictive maintenance is not just an opportunity to reduce costs and risks, but a fundamental step towards achieving resilient, digital, and future-oriented construction.