In the construction sector, characterized by complex projects, high resources, and often tight timelines, cost control is one of the most strategic tools to ensure the economic sustainability and management efficiency of a project. It is not an ancillary activity, but an integrated and continuous process that accompanies all phases of the construction cycle: from preliminary design to testing and subsequent management of the building.

Cost control is not just about monitoring incurred expenses: it involves forecasting, planning, and comparing estimated and actual values, allowing for the anticipation of critical issues, prevention of cost overruns, and optimization of resource use. Its importance grows further in a context where error margins are reduced due to increasing competition, variability in raw material prices, and the need to comply with regulatory and sustainability constraints.

Cost control is closely linked to:

It represents an essential tool for managing the complexity of construction projects. It is not limited to an accounting check, but represents a strategic process that integrates planning, monitoring, and resource management.

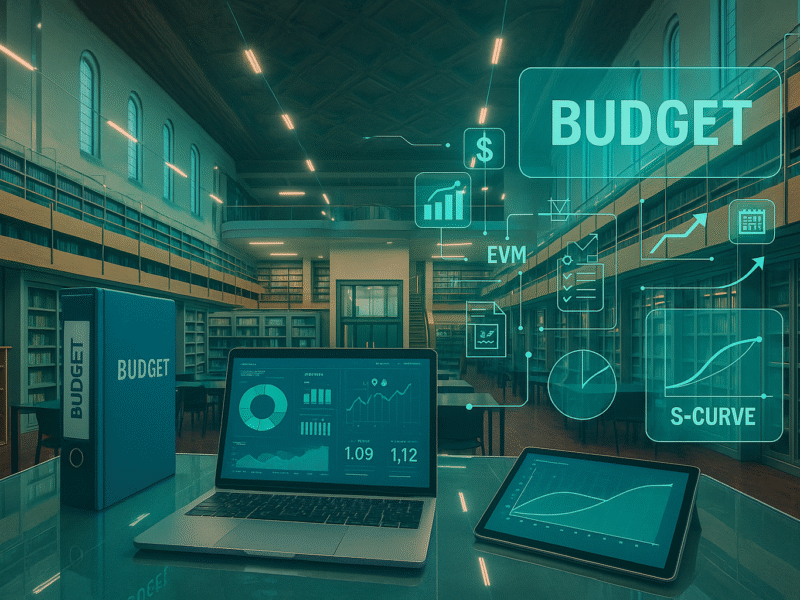

Through established methodologies such as EVM, advanced digital tools like BIM 5D, and innovative approaches like Life Cycle Costing, it is possible to transform cost control into an added value element, capable of ensuring not only compliance with economic limits but also the quality, sustainability, and competitiveness of the project.

Ultimately, cost control in construction is not a passive surveillance activity, but a governance lever to transform projects into efficient, durable works consistent with the objectives of the client and the community.