In the construction sector, the complexity of processes, the high number of stakeholders involved, and the multitude of variables at play make systematic progress monitoring essential. This practice is not limited to occasional checks on the progress status but constitutes a structured and continuous process that allows verification of the alignment of the work with what was planned in the design and contractual phases.

Monitoring allows for risk reduction, delay prevention, and management of potential issues before they become structural or economic problems. It is also a strategic lever to ensure transparency, quality, and sustainability, while providing objective data to support decision-making.

Effective monitoring is based on the definition of Key Performance Indicators (KPI), such as:

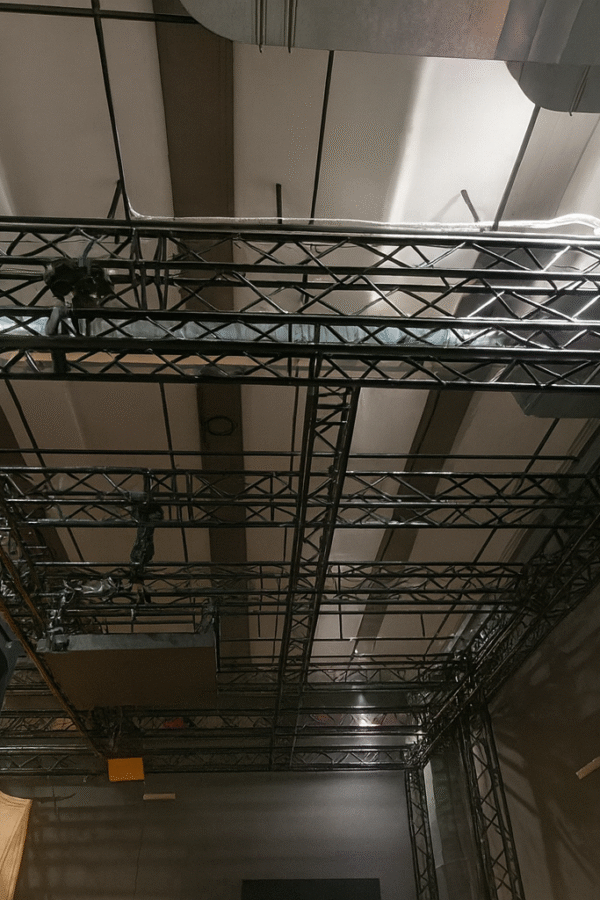

Progress monitoring should not be seen as an accessory activity but as a continuous process that accompanies all phases of construction. From the pouring of foundations to the final testing, systematic control allows the project to be kept under constant surveillance, improving the overall effectiveness of the construction process. Additionally, the data collected becomes valuable for the operational phase of the work, feeding into facility management and predictive maintenance systems.

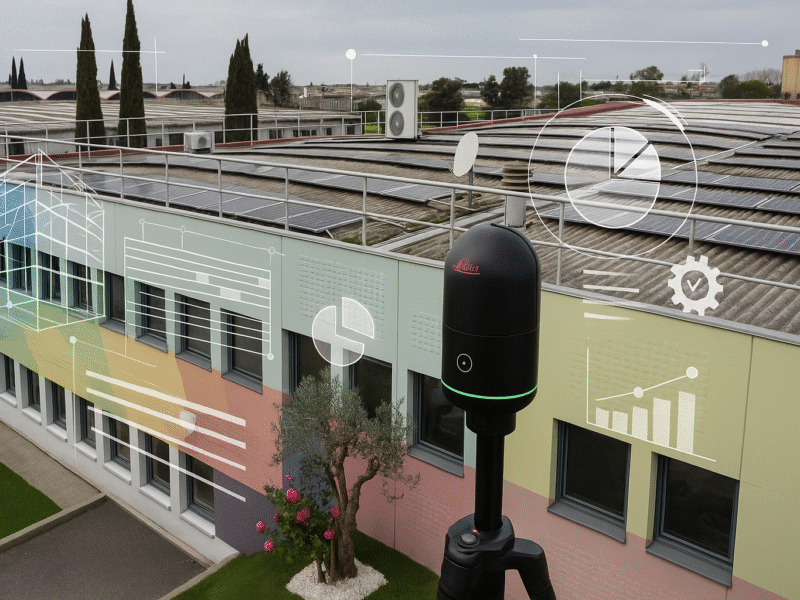

Progress monitoring is a cornerstone of project management in construction. Through traditional and digital tools, advanced methodologies, and objective indicators, it is possible to manage the complexity of construction sites, ensure quality, safety, and sustainability, and adhere to planned times and costs.

In an increasingly competitive and transparency-oriented sector, monitoring becomes not only an operational practice but a true governance strategy: an investment to reduce risks, improve performance, and enhance the value of the work throughout its entire life cycle.