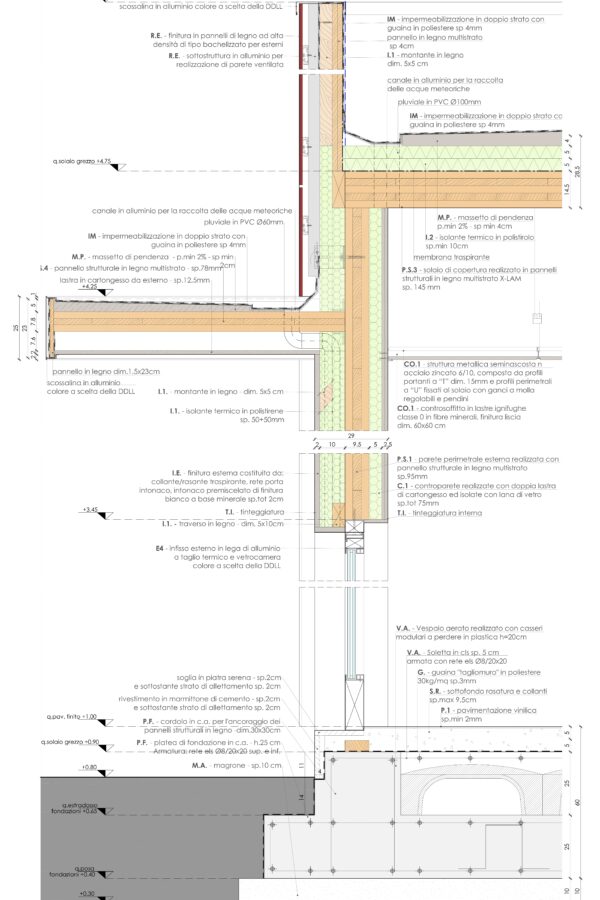

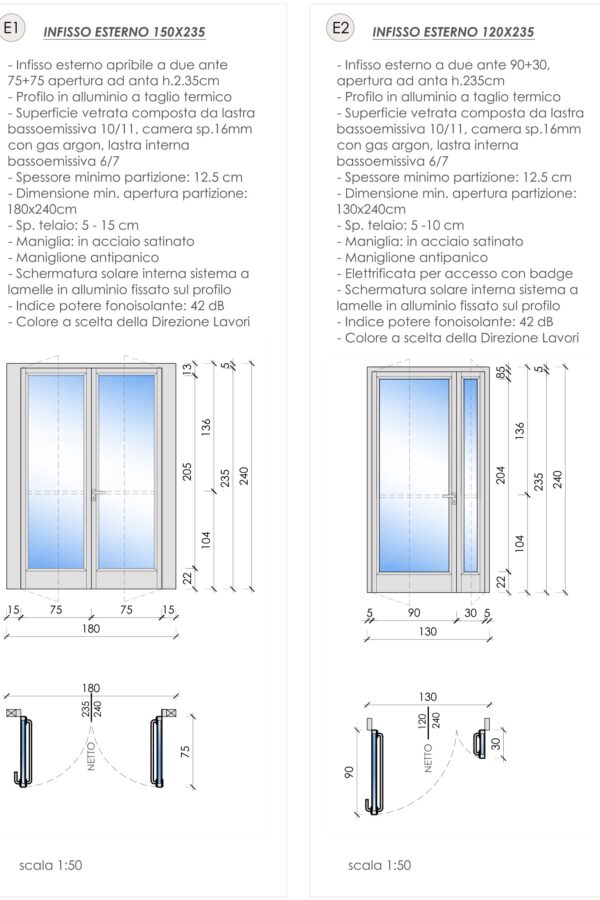

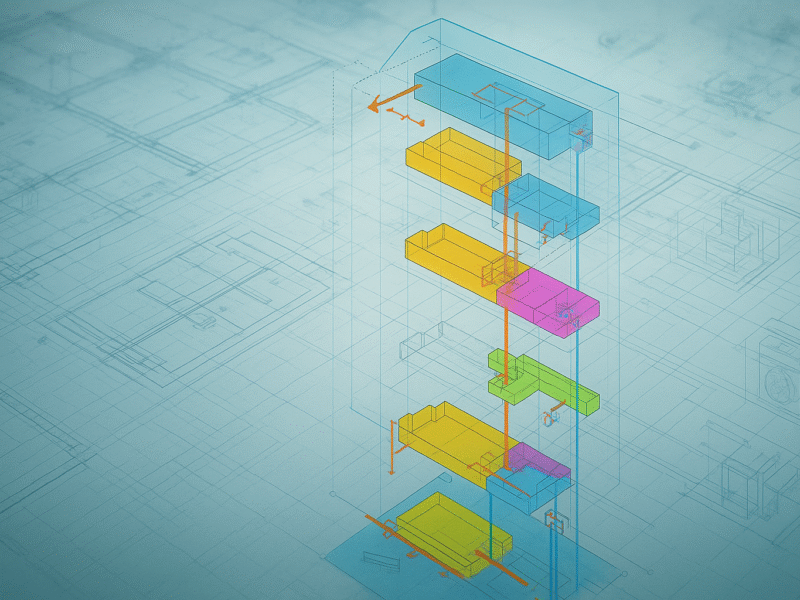

In the building design process, the graphical representation of technological and plant systems through functional diagrams and schematics plays a crucial role. These tools are not merely visual representations but actual logical and technical models that allow for understanding, coordinating, and controlling the operation of the various components of a building.

Their importance becomes particularly evident in detailed executive design, where the accuracy and completeness of information are essential to ensure that the project can be translated into an executable, safe, and high-performing work. Functional diagrams and schematics reduce ambiguity, facilitate interdisciplinary collaboration, and support both the construction and maintenance and management phases of the building.

Functional schematics are simplified graphical representations that describe the behavior and interconnections of plant and technological systems. Functional diagrams, on the other hand, emphasize the operational logic of processes, illustrating the flows of energy, fluids, or information within a system.

Main Characteristics:

Functional schematics and diagrams accompany all project phases:

Functional schematics and diagrams are essential tools in detailed executive design, as they allow complex design concepts to be transformed into clear, shareable, and operational representations. Their adoption reduces risks, optimizes time, and improves the overall quality of the work.

Thanks to integration with modern digital technologies, these tools are no longer just static elaborations but become part of a dynamic ecosystem that supports design, construction, and management. Ultimately, investing in the accurate production of functional schematics and diagrams ensures technical reliability, execution efficiency, and long-term sustainability of building works.