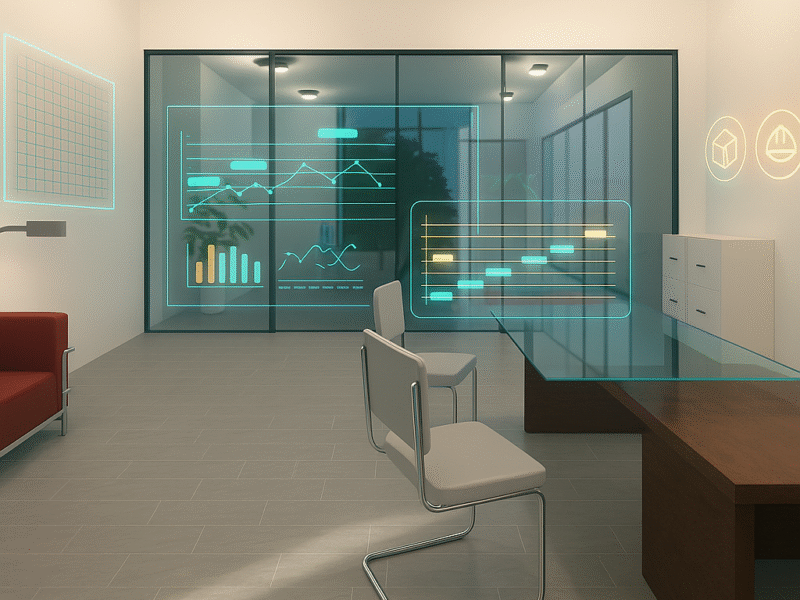

In managing a complex project, the correct allocation of resources is one of the most critical and strategic activities. In a sector characterized by stringent constraints on time, cost, and quality, the success of the project depends on the ability to allocate human, material, technological, and financial resources rationally and optimally.

Within the general contractor model, resource allocation assumes a central role: a single management must ensure that resources are planned, distributed, and monitored according to operational priorities and construction phases. Ineffective management leads to waste, delays, and cost increases; conversely, targeted allocation reduces risks, improves productivity, and ensures the project’s compliance with defined objectives.

Resource allocation develops throughout all operational phases:

Resource allocation is a key activity for the general contractor, as it allows managing the complexity of the site by transforming it into an orderly and efficient process. Through structured methodologies, digital tools, and a strategic vision, it is possible to optimize time, costs, and quality, reducing risks and increasing the overall sustainability of the project.

In an increasingly competitive construction context, resource allocation is not just a management activity but a fundamental organizational lever to ensure the success of complex projects, turning planning into tangible value for the client and the entire building lifecycle.