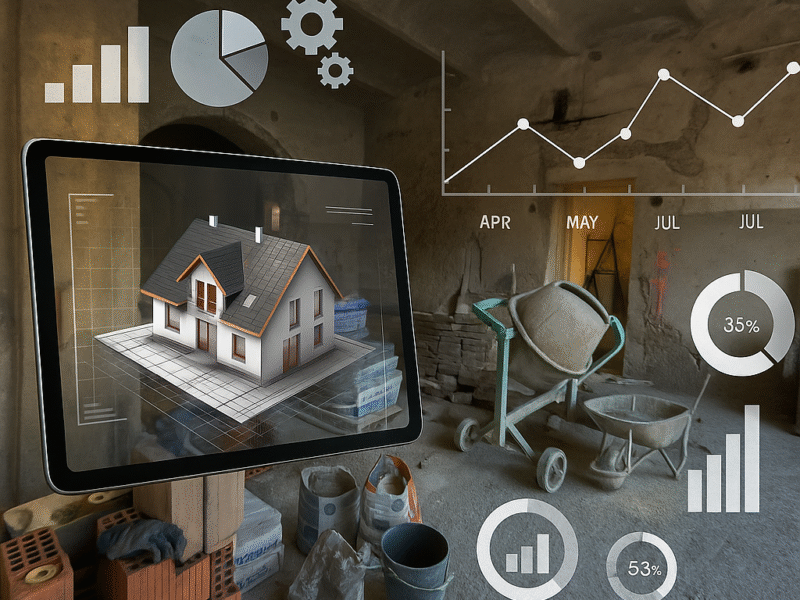

The control of site operations represents a crucial phase in the construction process, as it translates executive planning into practical activities, ensuring that each operation is carried out in compliance with timelines, costs, and project specifications. Without continuous and systematic monitoring, the risk of errors, inefficiencies, or non-compliance increases significantly, compromising the final quality of the work and negatively impacting the economic and environmental sustainability of the project.

In the context of detailed executive design, operational control is not just a supervisory activity but a true technical-management process that integrates digital tools, advanced project management methodologies, and quality protocols. This approach allows for the reduction of unforeseen events, anticipation of critical issues, and effective coordination of all parties involved on site, from executing companies to suppliers and specialized technicians.

Operational control accompanies all phases of the project:

The control of site operations is a strategic function that allows transforming the executive project into a real work, respecting time, costs, and quality. Through advanced methodologies and digital technologies, it is possible to ensure efficiency, safety, and sustainability, reducing risks and increasing transparency.

In a sector increasingly oriented towards precision and accountability, investing in structured operational control means not only supervising but proactively managing the construction process, ensuring that each phase contributes to the overall success of the project.